Вальцовая сухая грануляция (уплотнение на валках) — один из наиболее часто упоминаемых в последние годы способов гранулирования в порошковой переработке, который ценят за «меньше операций — выше эффективность». В отличие от традиционной влажной грануляции, здесь не требуется добавлять воду или растворители и, как правило, не нужно сушильное оборудование. Процесс основан на механическом воздействии: рыхлый порошок уплотняется в ленту/пластину, затем дробится и рассеивается, чтобы получить однородные гранулы. Для предприятий, чьи материалы боятся влаги и нагрева, а также для тех, кто стремится снизить энергозатраты и запылённость, вальцовая сухая грануляция часто становится более экономичным и стабильным технологическим маршрутом.

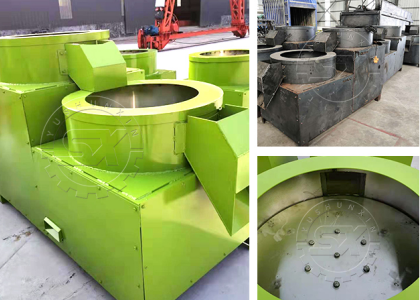

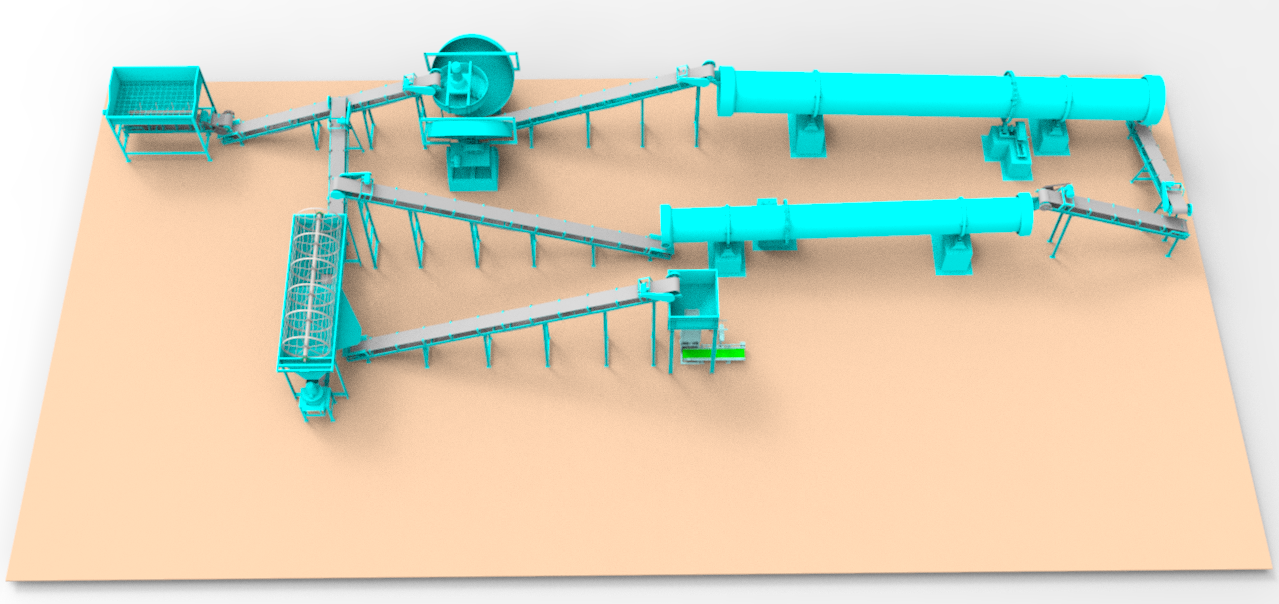

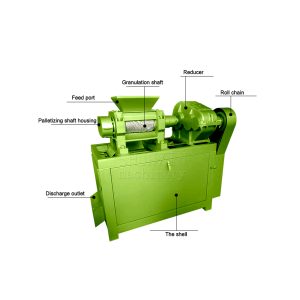

Двухвалковый гранулятор

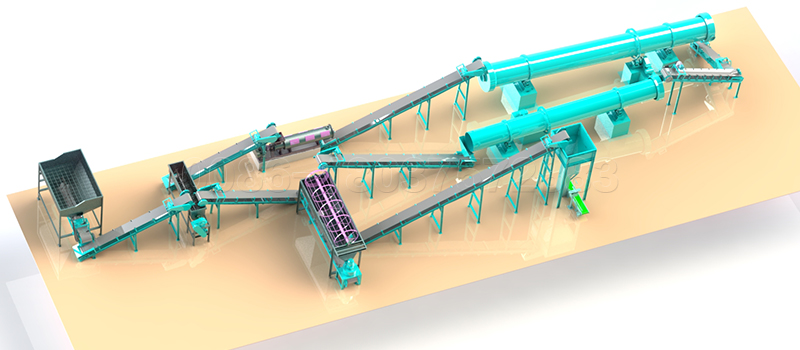

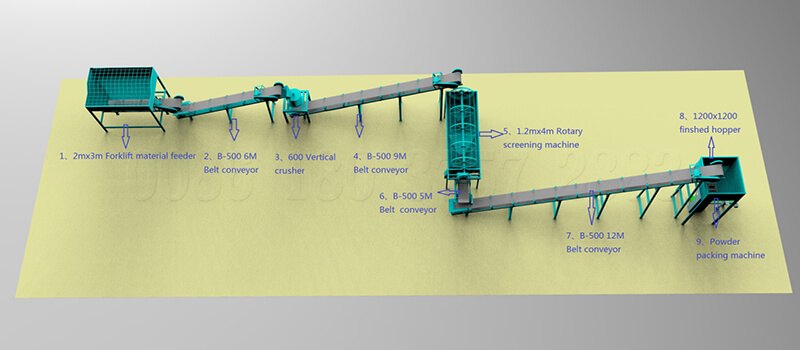

Базовую схему процесса можно свести к четырём этапам: стабильная подача — уплотнение на валках — калибровка/дробление — рассеивание с возвратом. Порошок из бункера через дозирующее устройство подаётся в зазор между двумя встречновращающимися валками и при заданных линейном давлении и зазоре уплотняется в плотную ленту (или пластину/«брикет»). Далее уплотнённый продукт поступает в калибратор (гранулятор/дробилку), где разбивается на более мелкие частицы. После рассеивания получают целевую фракцию готовых гранул; крупная фракция возвращается на повторное дробление, а мелочь — на повторное уплотнение, формируя замкнутый контур. Такая «закольцованная» схема повышает использование сырья и упрощает централизованное пылеулавливание, улучшая условия в цехе.

Преимущества вальцовой сухой грануляции прежде всего связаны с энергосбережением и упрощением процесса. Поскольку стадия сушки не нужна, существенно снижаются энергопотребление, площадь установки и объём обслуживания. Для термочувствительных или склонных к гидролизу материалов это также означает меньшие колебания качества по сравнению с влажными технологиями. Кроме того, уплотнённые гранулы обычно имеют более высокую насыпную плотность и лучшую текучесть, что повышает стабильность фасовки и дозирования, а также уменьшает пыление на последующих операциях (смешивание, транспортировка, таблетирование/подача). Технология хорошо подходит для непрерывного режима и автоматизации: регулируя подачу, скорость валков, линейное давление и зазор, можно в широких пределах балансировать производительность и гранулометрический состав.

При этом сухая вальцовая грануляция — не тот случай, когда «достаточно поставить оборудование, и гранулы сами получатся». Ключ — в правильном подборе параметров. На выход гранул, их прочность и долю мелочи сильнее всего влияют: гранулометрия исходного порошка и его влажность, прессуемость (хрупкость/пластичность), линейное давление, скорость валков, тип поверхности валков (гладкая или рифлёная), а также схема калибровки и сочетание сит. Типичные проблемы на производстве — «не формируется лента, лента хрупкая и легко ломается» — часто связаны с недостаточным давлением, нестабильной подачей или слишком сухим материалом. «Прилипание к валкам, забивание» обычно вызваны повышенной влажностью, ростом температуры или высокой липкостью материала. «Высокая доля мелочи, слишком большой возврат» требует комплексной настройки: прочность ленты, скорость калибратора и параметры рассеивания (размер ячейки сита). При необходимости небольшое количество связующего или технологической добавки может заметно повысить прочность ленты и выход годной фракции, но это следует оценивать с учётом назначения продукта и нормативных требований.

При выборе оборудования и внедрении рекомендуется начать с лабораторных или пилотных испытаний: измерить прочность и «упругий отскок» уплотнённой ленты при разных давлениях, построить зависимости «давление — плотность — гранулометрия — доля мелочи», а затем, исходя из целевого размера гранул, производительности и требований к прочности, подобрать подходящий размер валков, тип калибратора и конфигурацию пылеулавливания. В целом вальцовая сухая грануляция — это непрерывная технология гранулирования, где ключевым является уплотнение; она особенно хорошо подходит для задач с приоритетом низкого энергопотребления, малой запылённости и стабильной гранулометрии. При правильном согласовании подачи, уплотнения, калибровки и рассеивания можно получать гранулы с хорошей прочностью и текучестью без добавления жидкостей. Подробнее: добро пожаловать на наш сайт:https://www.sxmashina.com/rolikovyy-granulyator/

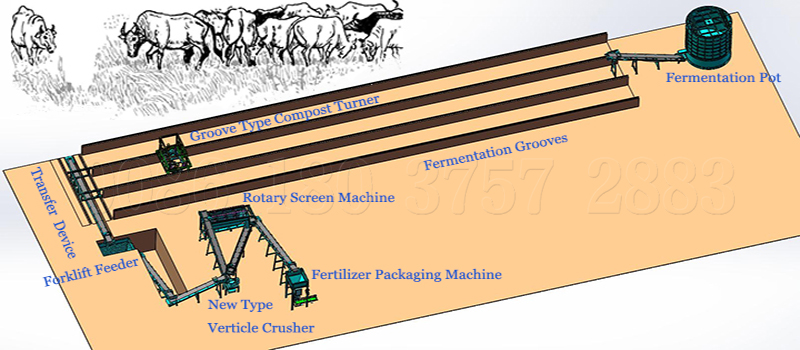

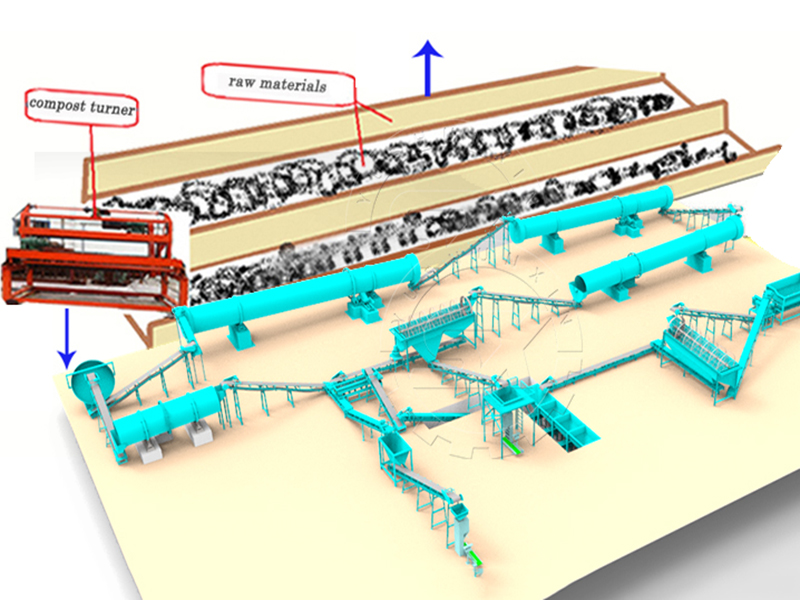

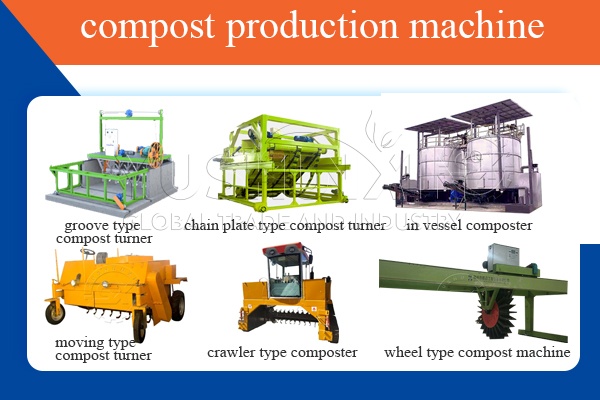

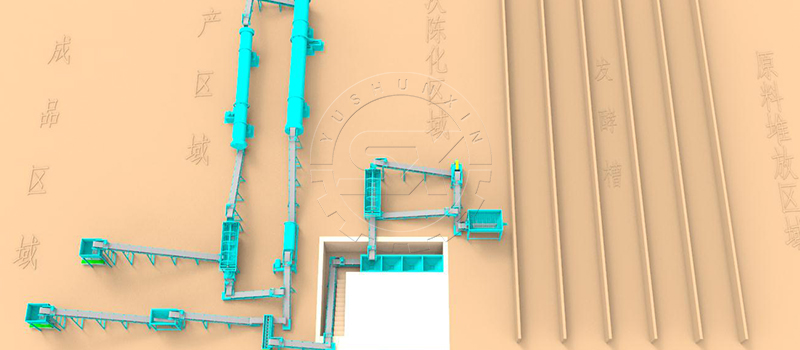

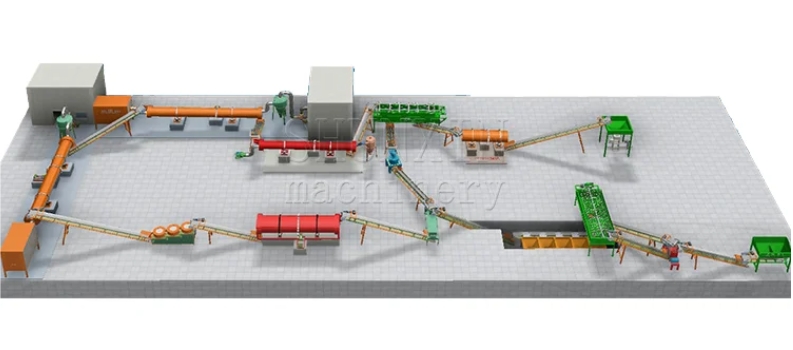

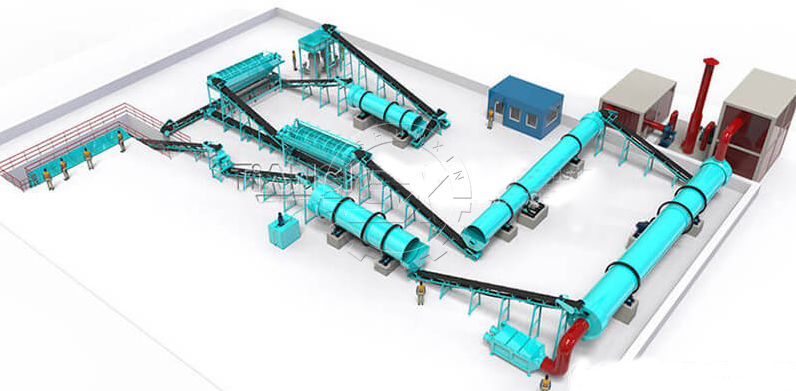

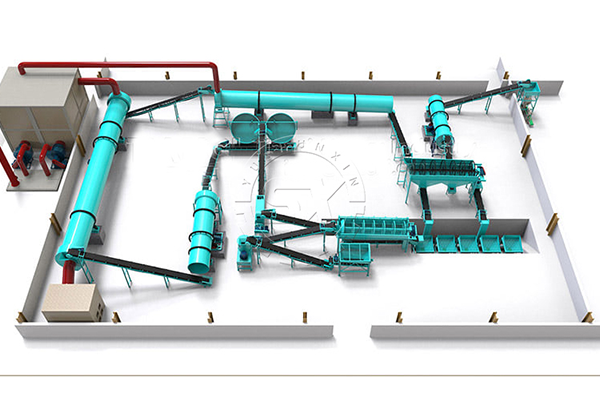

The demand for these systems has increased, primarily because of the need for more fertilizer for the ever-growing farming industry. Therefore, some research must be done to find these businesses, some of which will give you an exceptional offer on one of their best Windrow composting systems. Go to

The demand for these systems has increased, primarily because of the need for more fertilizer for the ever-growing farming industry. Therefore, some research must be done to find these businesses, some of which will give you an exceptional offer on one of their best Windrow composting systems. Go to